Sweets and snacks are very popular worldwide. In Germany alone for example, each person eats 30 kilograms per year. Regardless whether protein bars or classic milk chocolate—the taste and texture must be perfect in order to keep customers buying. The production process technology of these products plays an important role in achieving this. In particular, Ploughshare® Mixers are extremely flexible in their applications and thus ideally suited for the various requirements of the confectionery industry.

Some of the key processes involved in the production of sweets and snacks are homogenisation, conching and coating. The use of Ploughshare® Mixers has proven successful in all three processes. These mixers operate based on the mechanically generated fluid bed, which Lödige introduced to industrial mixing technology.

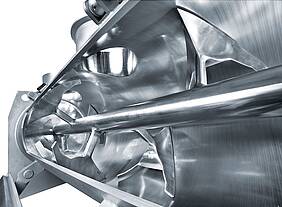

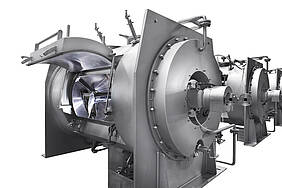

The operating principle can be described briefly as follows: Ploughshare® Shovels arranged on a shaft in a special system rotate as mixing elements in a horizontally fitted, cylindrical drum. These create a three-dimensional movement of the components intended for mixing. The resulting mechanically generated fluidised bed ensures fast, gentle and precise mixing. The separation of the particles in the fluidised bed makes adding liquids and coating the particles very easy. If needed, the mixing process can also be supported by high-speed rotating choppers. Thanks to their flexibility, Ploughshare® Mixers are very versatile in their range of applications. Three examples perfectly showcase the possibilities these machines bring to the confectionery industry.

Creamy smooth chocolate with the single-shaft Ploughshare® Conche

In the production process of chocolate, conching is understood as the transformation of a crumbly rolled material into a free-flowing suspension with clearly defined rheological and sensory properties—with as little dilution as possible through the addition of cocoa butter.

The process engineering for conching basically functions as follows:

- Dry conching

- Plasticising

- Liquefying

The conche invented by Rudolphe Lindt in 1879 required 72 hours in order for the chocolate to achieve its creamy smooth consistency. Today, chocolate manufacturers are looking for more cost effective, and above all, quicker alternatives to the traditional conche. An effective conching tool is, for instance, a Ploughshare® Mixer with appropriately modified shovels.

The design of the side walls ensures formation of large product surfaces during the drying phase. Because the particles are separated in the fluidised bed, they come into contact with air more vigorously and more frequently. The design and adjustment of the base plate in relation to the tempered mixing drum wall allows the introduction of high frictional energy. Due to the shape of the tools and their systematic arrangement on the mixer shaft the mass is continuously, entirely and vigorously mixed, so that a lump-free, homogeneous end product results.

Control of the process is dependent on output and time, and the rotational speed is regulated by the power consumption of the motor. Targeted temperature equalisation of the mass takes place via the application of warm or cold water running through the double jacket of the drum wall. Larger mixers require scrapers on the endplates. Additional nozzles are installed on the endplates for the injection of purified compressed air. This supports the discharge of vapours that arise during the conching process. With comparable product quality, this system is capable of significantly reducing processing time.

The perfect crunchy topping: Coating of crispies

Many products only obtain their specific shape and property once they are coated. The procedure is always used when surface properties of raw products need to be modified—for instance when the raw products must be protected or the taste is to be enhanced in some way. Coating processes are mainly performed on drum coaters, fluidised bed machines or mixers.

The selection of the right process technology essentially depends on the size of the particle and the structure of the product. Another deciding factor is the investment and operating cost, which depends on the added value of the product on the market. For instance, the acquisition cost for fluidised bed machines is roughly five times higher than for a mixer. However, ambitious coating tasks can also be realised with a Ploughshare® Mixer that is comparatively more cost-effective.

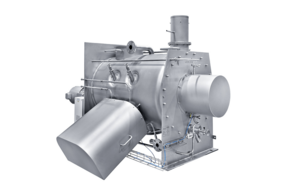

A solution that Lödige developed for coating grain extrudates—so-called crispies— demonstrates the possibilities of using a Ploughshare® Mixer for coating solutions in the confectionery sector.

Specifically, a number of requirements had to be taken into consideration in the development of the machine: The product to be coated has an almost round shape and a porous surface. The size of the particle varies according to the grain type. Likewise dependent on the type, up to tenfold the amount of liquid chocolate and/or fat can be applied. The crunchy properties of the crispies must be preserved. The finished product is then packaged separately as e.g. a crunchy topping for yoghurt.

The coating process in the Ploughshare® Mixer takes place as follows: The raw crispies are put into the mixing drum at room temperature. An expanding fill level for the weighted sample must be ensured. The rotational speed of the mixer is adjusted to form a moderate, yet vigorous fluidised bed. The liquid chocolate and fat masses are applied to the bed via open tubes. A pump is used for dosing.

The vigorous movement of the product as well as the frequent rubbing together of the individual crispies in the fluidised bed ensures uniform distribution of the liquid mass onto the surface of the crispies. The first layer coats the porous surface and creates a better bonding surface for further coating layers. So that the crispies don’t stick together (twinning or forming blackberry shapes), liquid nitrogen is continually injected directly into the product bed, in order to uniformly crystallise the applied coating mass. The process and the surface appearance can also be influenced by temperature equalisation of the mixing drum below the melting temperature of the liquid mass. The process parameters such as rotational speed, temperatures, quantity of molten chocolate and fat added, as well as the amount of nitrogen per unit of time must be adapted to the respective recipe. The batch reproducibility is ensured by adhering to the predetermined parameters.