Lödige as a partner for the

environmental industry

Lödige mixing and reaction systems can be used for mixing, generating/supporting reactions, granulation, neutralisation, compacting and liquefying/creating substances capable of being pumped.

Our dryers can be heated directly or indirectly through various methods and can continue operation throughout the viscoplastic product phase. Lödige vacuum dryers can lower boiling points for stripping problematic solvents.

Lödige reactors permit sterilisation processes - even combined with several other process steps.

Shaft seals and safety devices are available for all systems so that processes remain safe and reliable even under inert conditions.

Process engineering solutions

Positive environmental technology using Lödige mixing, reaction and high-temperature devices means converting waste substances of industrial and consumption processes into usable substances. Lödige solutions are perfect for this purpose - over 1,000 units delivered in the past years have proven that.

Lödige mixing, reaction and high-temperature systems are extremely flexible so that locally differing demands can be met with ease. Some examples of installed applications:

- conditioning and stabilisation of slurry

- treatment of compost made of various organic waste substances

- treatment of substitute fuels

- immobilisation of waste materials

- treatment of combustion residues

- lowering of boiling points of problematic fluids

- refinery and drill sludge conditioning

- recycling of residues from the metallurgy industry

- formulation of compounds for catalysts

- increasing absorption capacity of auxiliary substances for flue gas desulfurisation

- preparation of substances for underground reutilisation

- use of waste products for battery mass production

Machines for the environmental industry

Lödige offers machines adapted specifically to different process applications. Check the following list for an overview of the individual machines:

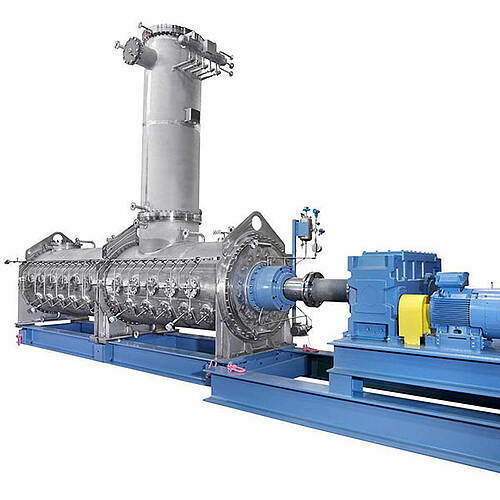

Granulation dryer for continuous operation

Combination of convection and contact drying Process management at low temperatures Gentle product treatment Simultaneous product granulation possible Reliable reproducibility of product quality Suitable for stripping processes High system availability

Ploughshare® Mixer (Laboratory machine)

Guaranteed Lödige quality Attractive value for money Functional design Ideal for your product and process development Extensive range of accessories

Ploughshare® Mixers for batch operation "Universal Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks. Extremely high mixing quality Short mixing times Reproducibility of batches Gentle product treatment High availability Low-maintenance mixer concept Easy accessibility of all internal mixer components Multi-stage processes in one machine

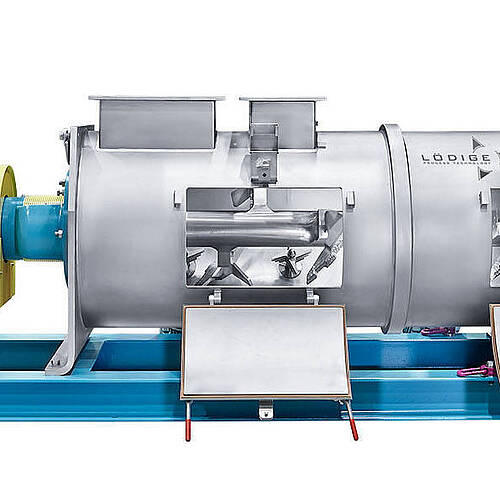

Ploughshare® mixers for continuous operation "Universal Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks. Excellent homogeneity of the final product Retention/mixing times and granulation processes can be adapted to the specific product Gentle product treatment Consistent reproducibility High availability Easy accessibility of all internal mixer components Low-maintenance mixer concept

Reactor DRUVATHERM®

Rapid uniting of reacting agents Prevention of local overconcentrations No temperature gradients within the reaction field Improved conversion of reactin agents, leading to higher yield with greater purity of the final product Multi-phase process (reaction, heating, drying, granulation, cooling)

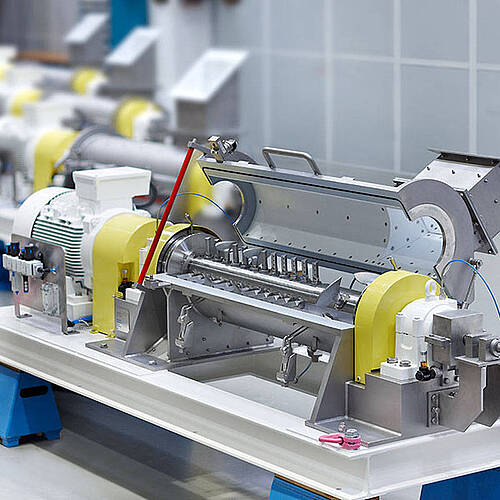

Reactor DRUVATHERM® (Laboratory machine)

DRUVATHERM® reactor at laboratory scale Rapid uniting of reacting agents Prevention of local overconcentrations No temperature gradients within the reaction field Improved conversion of reacting agents, leading to higher yield with greater purity of the final product Multi-phase proceess (reaction, heating, drying, granulation, cooling)

Ringlayer mixer CoriMix® for continuous operation

Compact machine unit with high throughput Extremely high mixing homogeneity Versatile application options Easy operation and cleaning High operating reliability and service life

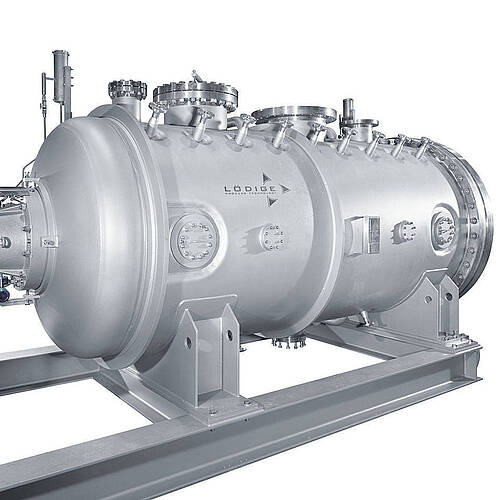

Vacuum shovel dryer DRUVATHERM®

Intense mixing prevents temperature and moisture gradients within the product Maximum heat transfer coefficients ensure excellent dryer performance Gentle thermal product treatment in vacuum mode Multi-phase process (mixing, granulation, drying, cooling) Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

Reliable scale-up Production development under consideration of industrial factors “All-in-one process” (mixing, granulation, drying, cooling) Intense mixing prevents temperature and moisture gradients within the product Short drying times through intense product movement and effective application of thermal energy Gentle thermal treatment at low temperatures using a strong vacuum Cost-efficient solvent recovery

Applications for the environmental industry

Our system solutions are popular in the field of environmental technology. Our mixing and granulation processes are particularly used in the following facilities with great success:

- Power plants

- Steel plants

- Sewage treatment plants

- Waste incinerating plants

- Underground/open-cast mining

- Disposal industry

Downloads

System solutions for the environmental technology

Download PDF »

Stabilizing power station byproducts